- Heat activatable back coating for high frequency welding, ultrasonic welding, hot air welding or iron on

Available from 500 m order quantity

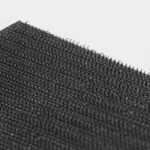

- Hook tape & loop tape 100% polyamide (Nylon), woven

- Nominal width (Commercial classification): 100 mm

- Hook tape width across the board: 110 mm

- Width of the hook trim: 105 mm

- Loop tape width across the board: 100 mm

- Width of the loop trim: 97 mm

- Thickness: 2 mm

- Back pre-coated with non-tacky, heat activatable dry adhesive for quick, permanently durable, waterproof bondings

- Can be processed by high-frequency welding machine, hot air device, heat-pressing with roller or iron

- Ideal for durable, waterproof bondings with PVC products like raincoat, stationary, tent, truck tarpaulin, but also textiles made of synthetic or natural fibres such as curtains, decorations or bags & luggage

The ironing on of Velcro tapes is a welding process that uses heat and an auxiliary material to permanently join several components together.

- Never iron directly on the Velcro tape, but always on the other material with which you want to combine the Velcro tape. So only use the iron on the material of your product, which can be textile fabric or PVC.

-

Place the hook side respectively the loop side of the Velcro tape on a soft surface for ironing. Standard padding for ironing boards and ironing tables is suitable. The hooks of the velcro tape sink into the soft padding. This distributes the pressure generated during ironing better. As a result, less force impacts on each single hook. This reduces the risk that the hooks of the Velcro will permanently bend in case of unintentional overheating.

Place the hook side respectively the loop side of the Velcro tape on a soft surface for ironing. Standard padding for ironing boards and ironing tables is suitable. The hooks of the velcro tape sink into the soft padding. This distributes the pressure generated during ironing better. As a result, less force impacts on each single hook. This reduces the risk that the hooks of the Velcro will permanently bend in case of unintentional overheating. Temperature

The fastening tape with its hooks and loops is made of polyamide 6.6. Its melting point is 220°C. More important for processing with an iron, however, is the heat deflection temperature. For polyamide 6.6 it is 85°C according to the ISO 75-2 standard with test method A. The Velcro tape must not be heated permanently higher, otherwise the hooks will be deformed. This deteriorates the function of the Velcro fastener in general and reduces its closing force in particular. Accordingly, the washing temperature should not exceed 60°C.

However, the temperature value determined by the above-mentioned standardized test method cannot be transferred exactly to the Velcro tape, as the heat is distributed differently in the Velcro tape than in the standardized test specimen. The polyamide can even resist 180°C for a short time if it is not subjected to any load. During ironing, however, the iron presses at least with its own weight on the Velcro tape. The wider the Velcro tape, the better this pressure is distributed over the surface heated by the iron soleplate. With a wide Velcro tape, the hot iron may therefore press more and/or longer on the surface to be heated than with a narrow Velcro tape.

The lowest control stage of consumer irons, marked with 1 point, heats the soleplate to about 110°C. The soleplate transfers this temperature with losses to the material to be ironed, from there to the pre-coated melt adhesive and only then, after further losses, does it reach the polyamide of the Velcro tape. Depending on the type (natural fibre, such as cotton or linen, synthetic fibre such as polyester or polypropylene, PVC foil or PVC tarpaulin) and thickness of the material to be ironed, the heat of the iron soleplate penetrates the melt adhesive and the Velcro tape to a varying degree. Therefore we cannot name a generally valid ironing temperature. Instead, the processor has to test for himself- what temperature he sets on his iron and

- how long he allows the heat to act on the surface to be processed,

- Be sure to let the adhesive set for 24 hours after ironing to obtain full strength before washing.

- PU: 25 m roll